Road Tyre

Construction

From all choices is clincher tyre the heaviest. Necessity to use a much heavier inner tube that adds more weight and increases rolling resistance.

- Necessity to inner tube - an extra part and more weight

- Clincher tyre is heavier compare to tubular

- Higher rolling resistance compare to tubular

- In case of puncture is the repair possible (not easy) or the tube has to be changed

- No need to use glue, mounting is quite difficult and sometimes impossible without using tools

- After mounting it can be used immediately

- In case of fast deflation, direct and instant effect on the rider's stability and safety

- Road Tyres

- Compatibility rim chart

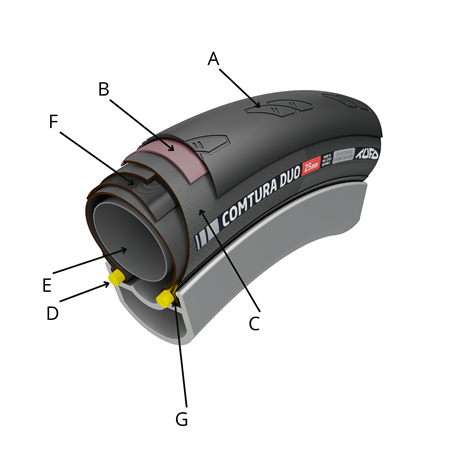

A

Tread

produced with natural rubber based compound with Activated Silica.

B

Protective rubber ply

located underneath the tread, indicates also tyre wear and higher possibility of punctures when showing through the tread (only in specified models).

C

The carcass

The carcass determines the shape, strength, and driving characteristics of the tyre. Its quality is often expressed in TPI units.

D

Standard aramid beads for tube type tyres

E

Inner Tube

F

Puncture barrier

The anti-puncture layer is a special reinforcement inside the tyre casing that protects against punctures and cuts.

G