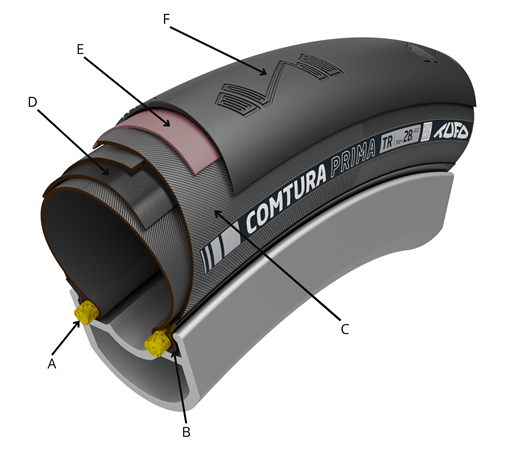

Comtura Prima TT Tubeless tyres TR

Training

30%

Racing

100%

The current standard for professional pelotons. Tubeless tyres combine the advantages of tubular tyres and tube systems – they offer low rolling resistance, greater riding comfort thanks to lower pressures, and significantly reduce the risk of punctures thanks to the use of sealant.

Tubeless technology has become popular mainly due to its versatility, safety, and performance—it allows for aggressive riding even on rough surfaces without the risk of puncturing the inner tube or removing the tyre. Most World Tour teams today choose this option as their primary racing solution.